English - Español

PRODUCTION PROCESS

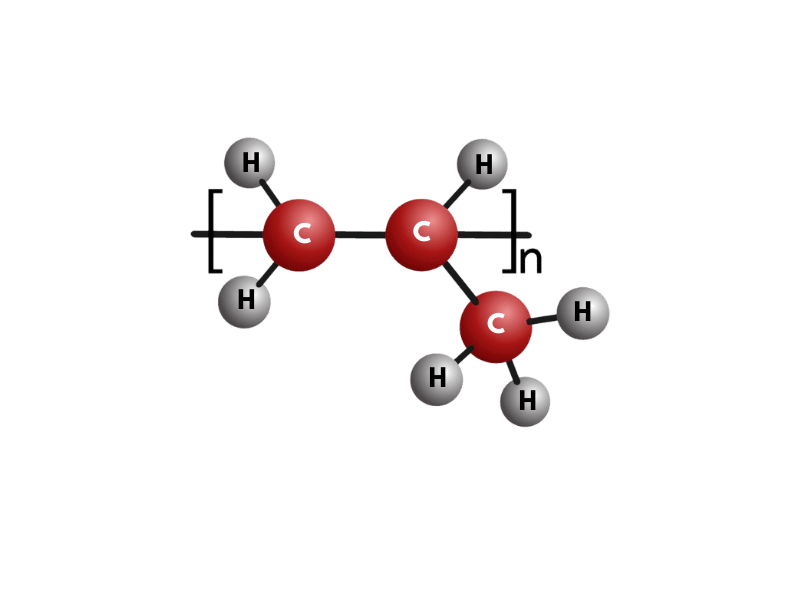

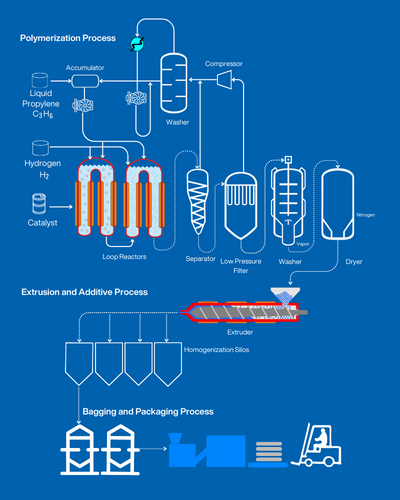

The process consists of transforming Propylene into Polypropylene (polymer), by using specific Ziegler-Natta type catalysts, through Spheripol® technology.

Once the desired polymer is obtained from the polymerization reaction (Loop Reactors), the product is sent to separation processes for the removal of the remaining propylene residues. Once the residues are removed, the product is sent to an additive process, where the necessary additives are incorporated to give the product the specific characteristics required for its final application.

Once that is completed, an extrusion process is initiated, and lastly it goes through a pelletizing process that results in the finished product for distribution to the market.

ALL UNDER EXHAUSTIVE QUALITY CONTROL